With tariffs climbing, global supply chains cracking, and geopolitical risks rising, more American founders are reshoring production. What used to be built almost exclusively in China is now being built here at home—not just as a patriotic move, but as a strategic one.

The benefits? Faster turnaround, fewer shipping headaches, higher perceived value, and access to U.S. grants and programs.

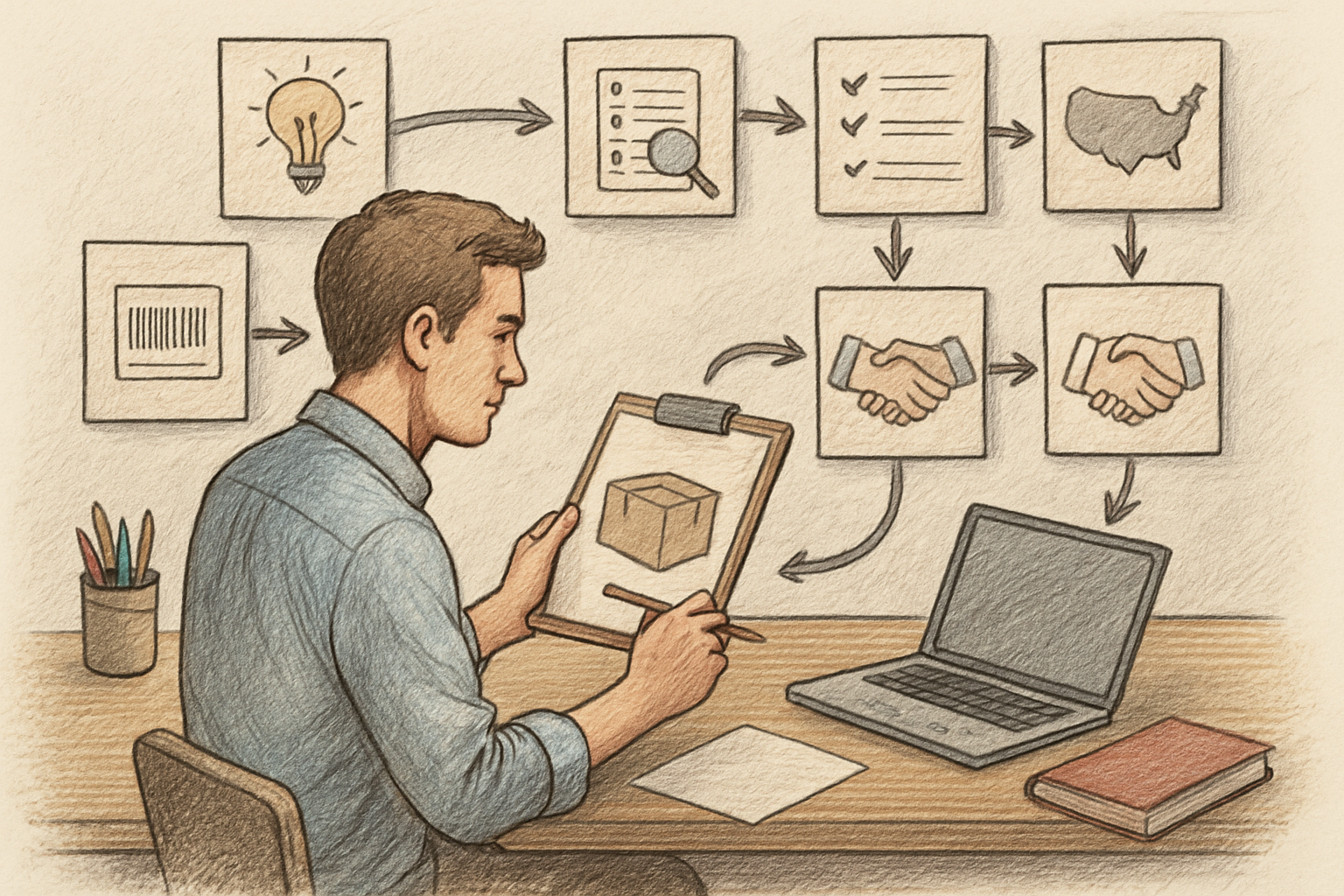

At Apex CEO, we work with product company founders navigating this shift. Here’s a practical, 8-step playbook to help you source and scale in the U.S.

Step 1: Validate the Product Opportunity

-

Research Amazon, Alibaba, Temu, and eBay to see what’s selling.

-

Identify “white space”—price tiers or features the market is missing.

-

Use AI tools or surveys to size your TAM and define your ideal buyer.

-

Walk trade shows to hear directly from buyers and distributors.

Step 2: Design & Engineer the Product

-

Hire U.S.-based engineers under Work-for-Hire Agreements so you own the IP.

-

Ensure they understand UL/Intertek standards if electronics or safety are involved.

-

Build a Bill of Materials (BOM) with part drawings, specs, and numbers.

Step 3: Protect with a Patent

-

Remember: first-to-file wins under U.S. law.

-

A utility patent strengthens pricing power and protects against knockoffs.

-

Work with an attorney specialized in your industry.

Step 4: Leverage Government & State Resources

-

Tap your state’s Manufacturing Extension Partnership (MEP) for vetted suppliers.

-

Come prepared with a BOM, drawings, and an assembly sketch.

-

Explore NSF, SBA, and EXIM for grants, supplier connections, and export readiness.

Step 5: Begin Supplier Outreach

-

Use Thomasnet.com and filter by geography.

-

Treat suppliers like investors: bring drawings, specs, and realistic volumes.

-

Expect a network of vendors—not one factory—to build your product.

Step 6: Do Deep Due Diligence

-

Call vendors, don’t just email.

-

Collect RFQs and compare apples-to-apples.

-

Visit sites for cleanliness, professionalism, and scale.

-

Hold joint engineering reviews to ensure alignment.

Step 7: Plan for Final Assembly

-

Contract manufacturers (CMs) can handle assembly, testing, and packaging.

-

Provide clear assembly documentation.

-

Negotiate turnaround times, MOQs, and testing protocols upfront.

Step 8: Align Sales Forecasts with Capacity

-

Separate your marketing forecast (what you hope to sell) from your production schedule (what you can build).

-

Example: 100,000 units/year = 416 units/day = 52 units/hour (on an 8-hour shift).

-

Suppliers will take you more seriously if you’ve done the math.

Final Thoughts: The Future Is Local

The road to “Made in the USA” isn’t always simple, but it’s increasingly strategic. Rising tariffs, consumer preference for American-made goods, and new incentives make domestic sourcing more attractive than ever.

At Apex CEO, we help founders navigate this shift—from ideation and engineering to supplier scouting, financial planning, and scaling.

👉 If you’re building a product and want to build it right, connect with me at www.apexceo.co.